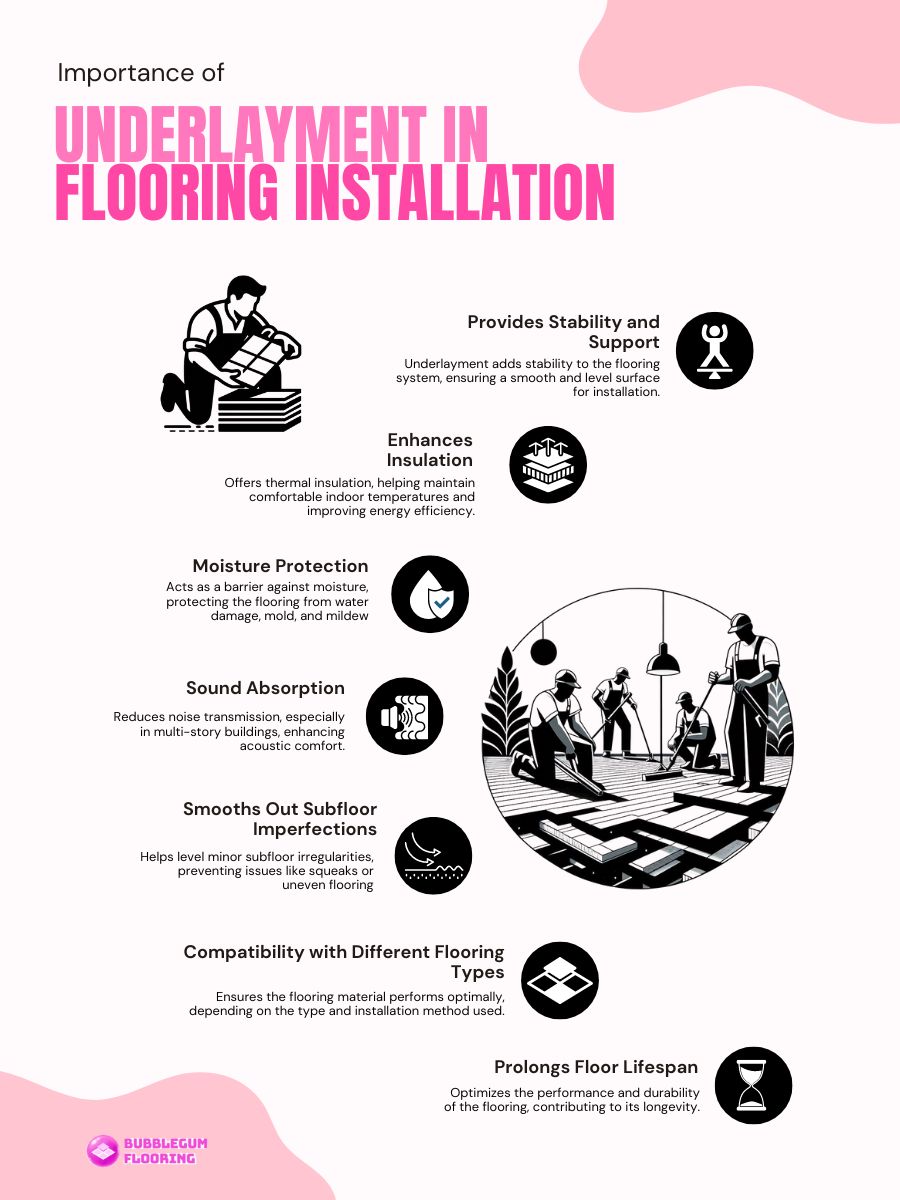

When it comes to flooring installation, the underlayment might not be the star of the show, but it plays a crucial supporting role that can’t be ignored. Underlayment serves as the unsung hero beneath your feet, providing stability, insulation, and moisture protection to ensure your floors stand the test of time.

Imagine your flooring installation as a building. The subfloor is the foundation, providing the base upon which everything else rests. But just like a sturdy foundation needs proper insulation and protection, your subfloor needs the support of underlayment to enhance its performance and safeguard against common flooring issues. Let’s talk about the importance of underlayment in flooring installation.

What is Underlayment?

The underlayment is a thin layer of material placed between the subfloor and the flooring surface. Its primary purpose is to provide support, stability, and additional benefits to the flooring system.

While the subfloor serves as the structural base, underlayment offers supplementary features such as insulation, moisture protection, sound absorption, and even cushioning underfoot. Essentially, underlayment acts as a buffer between the subfloor and the flooring material, optimizing the performance and longevity of the entire floor.

Why Choose the Right Underlayment Material?

Not all underlayment materials are created equal, and choosing the appropriate type is important for achieving optimal results in your flooring project. Factors such as the type of flooring being installed, the environmental conditions of the space, and specific performance requirements will dictate the selection of underlayment material.

For instance,

- A moisture-prone area like a bathroom may require underlayment with excellent water resistance.

- A sound-sensitive environment such as a condominium may benefit from underlayment with superior soundproofing qualities.

Choosing the right underlayment material ensures compatibility with the flooring type and addresses the unique needs of the installation site, ultimately contributing to the overall success of the project.

Types of Underlayment

To choose the best underlayment for your flooring project, you need to be aware of the numerous kinds that are available. Each type has unique qualities and advantages that are suited to particular flooring materials and installation needs.

1. Foam Underlayment

Foam underlayment is one of the most commonly used types due to its versatility and affordability. Typically made from materials like polyethylene or polystyrene, foam underlayment provides cushioning underfoot, minimizes noise transmission, and helps smooth out minor subfloor imperfections.

Its lightweight nature makes it easy to handle and install, while its moisture-resistant properties make it suitable for a wide range of flooring applications, including laminate, engineered hardwood, and luxury vinyl plank (LVP) installations.

2. Cork Underlayment

Cork underlayment offers unique properties that set it apart from other types of underlayment. Made from the bark of cork oak trees, cork underlayment is a sustainable and eco-friendly option known for its excellent sound absorption capabilities and thermal insulation properties.

It also provides a resilient and comfortable surface to walk on, making it ideal for areas where comfort and noise reduction are priorities, such as bedrooms and living rooms. Cork underlayment is also naturally resistant to mold, mildew, and pests, making it a popular choice for areas prone to moisture.

3. Rubber Underlayment

Rubber underlayment, often made from recycled rubber materials, is prized for its durability and superior impact resistance. It excels at reducing noise transmission between floors, making it an excellent choice for multi-story buildings or condominiums where soundproofing is essential.

Rubber underlayment also provides excellent shock absorption, making it suitable for areas with heavy foot traffic or where comfort is a priority, such as gyms or playrooms. Its moisture-resistant properties and ability to withstand temperature fluctuations make it suitable for installation in basements and other moisture-prone areas.

4. Felt Underlayment

Felt underlayment, composed of recycled fibers or synthetic materials, offers a dense and stable surface ideal for supporting flooring materials like hardwood and engineered wood. It provides a smooth and level base for installation, helping to prevent premature wear and damage to the flooring above.

Felt underlayment also offers moderate sound absorption properties, making it suitable for use in residential spaces where noise reduction is desired. Its thermal insulation properties help improve energy efficiency by reducing heat loss through the floor, making it a popular choice for colder climates.

Matching Underlayment with Flooring Types

To ensure the longevity, functionality, and comfort of your floors, choose the right underlayment for the type of flooring you have. For best effects, match different flooring materials with the appropriate underlayment. Each flooring material has certain qualities and installation needs.

1. Hardwood Flooring

For hardwood flooring installations, experts often recommend using felt underlayment due to its dense and stable composition. Felt underlayment provides a smooth and level surface, helping to prevent the transfer of subfloor imperfections to the hardwood planks.

It also offers moderate sound absorption properties, reducing noise transmission and enhancing the acoustics of the room. When installing hardwood flooring, it’s essential to select underlayment that is compatible with the installation method and the type of hardwood being installed.

- Floating hardwood floors, for example, require underlayment with moisture barrier properties to protect against moisture damage.

- Additional cushioning and impact absorption in the form of underlayment may be advantageous for nail-down installations.

2. Laminate Flooring

When installing laminate flooring, foam underlayment is often recommended due to its cushioning properties and moisture resistance. Foam underlayment provides a smooth and stable surface for laminate planks, helping to reduce noise and absorb minor subfloor imperfections.

It also acts as a moisture barrier, protecting the laminate flooring from moisture damage and prolonging its lifespan. The choice of underlayment for laminate flooring may be influenced by factors such as the installation environment, subfloor condition, and specific performance requirements.

- In areas prone to moisture, going for underlayment with superior water resistance is essential to prevent mold, mildew, and damage to the laminate flooring.

- In multi-story buildings or condominiums, choosing underlayment with excellent soundproofing properties can help reduce noise transmission between floors and improve overall comfort.

3. Vinyl Flooring

For vinyl flooring installations, underlayment with moisture resistance is crucial, especially in areas prone to water exposure such as bathrooms, kitchens, and laundry rooms. Foam underlayment with built-in moisture barriers or cork underlayment, known for its natural resistance to moisture, are popular choices for vinyl flooring installations.

These underlayment materials not only protect the vinyl flooring from moisture damage but also provide additional cushioning and sound absorption benefits. Vinyl flooring, particularly luxury vinyl plank (LVP) and luxury vinyl tile (LVT), is highly resistant to moisture, making it suitable for wet areas like bathrooms and kitchens.

However, moisture can still seep through the seams and edges of vinyl flooring, potentially causing damage to the subfloor.

4. Tile Flooring

When installing tile flooring, especially ceramic or porcelain tiles, underlayment materials such as cement backer board or uncoupling membranes are commonly used to provide a stable and level surface. Cement backer board, composed of cement and fiberglass mesh, offers excellent support and moisture resistance, making it ideal for tile installations in wet areas like bathrooms and showers.

Uncoupling membranes, on the other hand, provide a flexible and crack-isolation layer that helps prevent cracks in the tile and grout caused by subfloor movement. Tile flooring installations require a flat and stable subfloor to ensure proper adhesion and prevent tile cracking or grout failure.

Therefore, using underlayment materials like cement backer board helps level uneven subfloors and provide a solid foundation for tile installations. Additionally, uncoupling membranes allow for slight movement between the subfloor and tile layer, reducing the risk of cracks caused by substrate movement or expansion.

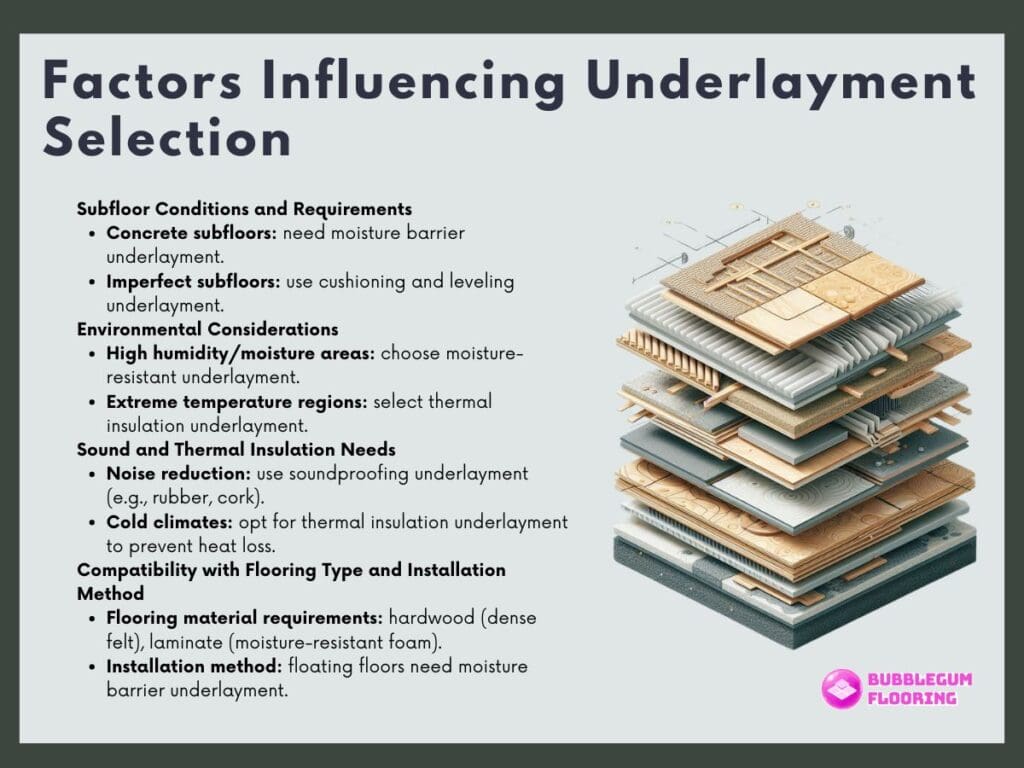

Factors Influencing Underlayment Selection

Several factors should be taken into account when selecting the appropriate underlayment for your flooring project. Understanding these factors will help ensure that you choose the right underlayment material that meets the specific needs of your installation.

1. Subfloor Conditions and Requirements

The type of subfloor you have will influence your underlayment selection. For example, concrete subfloors may require underlayment with moisture barrier properties to prevent moisture from seeping into the flooring material.

If your subfloor has minor imperfections such as unevenness or small cracks, selecting underlayment with cushioning and leveling properties can help create a smooth and stable surface for the flooring installation.

2. Environmental Considerations

In areas with high humidity or moisture, such as basements, bathrooms, or kitchens, choosing underlayment with excellent moisture resistance is crucial to protect the flooring material from water damage and mold growth.

In regions with extreme temperature fluctuations, selecting underlayment with thermal insulation properties can help improve energy efficiency and maintain comfortable indoor temperatures.

3. Sound and Thermal Insulation Needs

If reducing noise transmission between floors is a priority, selecting underlayment with soundproofing properties, such as rubber or cork, can help minimize impact noise and improve the acoustics of the space.

In colder climates, choosing underlayment with thermal insulation properties can help prevent heat loss through the floor, improving energy efficiency and maintaining a comfortable indoor temperature.

4. Compatibility with Flooring Type and Installation Method

Different types of flooring materials may require specific underlayment types to support their installation and enhance their performance. For example, hardwood flooring may benefit from dense felt underlayment, while laminate flooring may require moisture-resistant foam underlayment.

The installation method used for your flooring, such as floating, nail-down, or glue-down, will also influence your underlayment selection. For floating floor installations, underlayment with built-in moisture barrier properties is typically recommended to protect against moisture damage.

Installation Tips and Best Practices

Proper installation of underlayment is essential for maximizing its effectiveness and ensuring the success of your flooring project. Here are some tips and best practices to follow during the installation process:

1. Pre-Installation Preparation:

Before installing underlayment, ensure that the subfloor is clean, dry, and level. Remove any debris, dust, or adhesive residue that may affect the adhesion of the underlayment.

Use self-leveling compound or patching compound to fill in any cracks, gaps, or uneven areas on the subfloor. A smooth and level surface will help prevent issues such as squeaks or gaps in the flooring.

2. Correct Installation Techniques:

When installing underlayment rolls or sheets, be sure to overlap the seams by several inches to prevent moisture infiltration. Use moisture-resistant tape to secure the seams and create a continuous barrier.

If using adhesive-backed underlayment, follow the manufacturer’s instructions carefully to ensure proper adhesion to the subfloor. Use a roller or heavy weight to press the underlayment firmly in place and remove any air bubbles.

3. Consider Moisture Protection:

In areas with high moisture levels, such as basements or bathrooms, consider installing a separate vapor barrier beneath the underlayment to provide an additional layer of protection against moisture infiltration.

Seal the edges of the underlayment with moisture-resistant tape or sealant to prevent moisture from seeping in around the edges and compromising the integrity of the installation.

4. Take Care with Transitions:

Install transition strips or moldings where the underlayment meets different flooring materials or transitions between rooms. This helps create a seamless transition and prevents tripping hazards.

Trim the underlayment neatly around obstacles such as door jambs, vents, or corners to ensure a clean and professional finish.

5. Maintenance and Care Guidelines:

Refer to the manufacturer’s guidelines for specific maintenance and care instructions for the underlayment material used. Proper maintenance will help prolong the life of the underlayment and preserve its performance.

Periodically inspect the underlayment for signs of wear, damage, or moisture infiltration. Address any issues promptly to prevent them from affecting the integrity of the flooring above.

Waterproof vs. Water-Resistant Flooring

Serving as the foundation for your floors, underlayment provides essential support, stability, and protection against common flooring issues such as moisture damage, noise transmission, and subfloor imperfections. One crucial consideration in flooring installation is the distinction between waterproof and water-resistant flooring materials.

While both offer some level of protection against moisture, they differ in their ability to withstand prolonged exposure to water. Waterproof flooring, such as luxury vinyl plank (LVP) or ceramic tile, is impervious to water and suitable for areas with high moisture levels, such as bathrooms, kitchens, and basements.

On the other hand, water-resistant flooring, like laminate or engineered hardwood, can resist water to some extent but may still be susceptible to damage if exposed to excessive moisture. Incorporating the right underlayment and flooring materials into your project ensures not only a visually appealing result but also a durable and functional floor that stands the test of time.